Long on the cutting edge of emerging technologies, IDIA Lab has gained a reputation for unique skill sets. Providing their photogrammetry and 3D printing services, IDIA Lab joined several departments in the production of the new exhibition at the David Owsley Museum of Art.

“The Power of Place: 100 Years of Architecture at Ball State University”

“The Power of Place: 100 Years of Architecture at Ball State University” showcases the ways Ball State’s campus architecture has changed and how the past still shines through.

“The exhibition embodies the idea that even though Ball State’s built environment has greatly changed over time by way of adding new buildings constructed with modern materials, our past is forever present,” says Rebecca Torsell, archivist for architectural records at Ball State University, who organized the exhibition.

Running from September 27 through December 21, 2018, the exhibition is part of a campus-wide celebration of Ball State’s Centennial.

“The museum is an ideal place to celebrate the University’s Centennial,” says Robert G. La France, director of the David Owsley Museum of Art. “For more than 80 years the museum’s building — the Fine Arts Building — has stood as Ball State’s palace to the arts. This show displays the University’s long-standing commitment to distinctive architecture and introduces visitors to its vast architectural archives and special collections.”

Photogrammetry

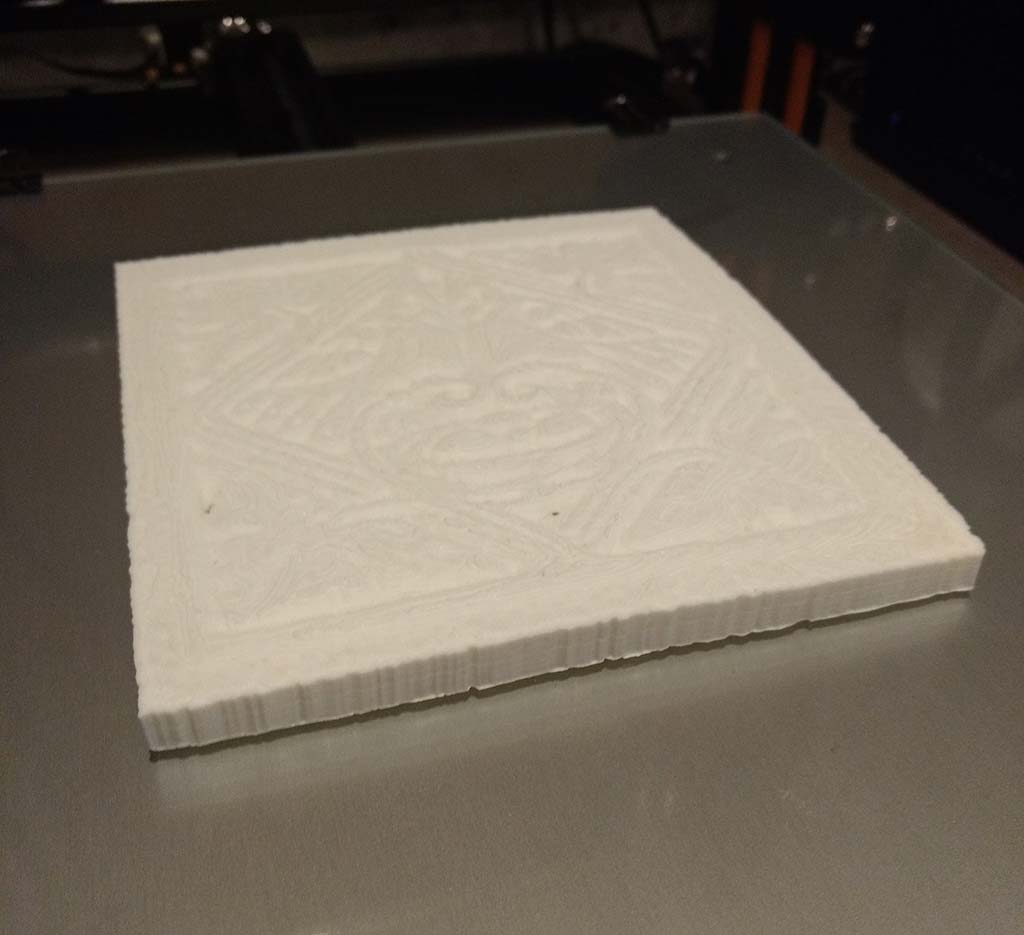

Part of the history of Ball State architecture includes unique tiles used in the Fine Arts Building itself. The museum wanted a way to display these ornate, relief tiles without removing them from the wall. Using their photogrammetry techniques, IDIA Lab first recreated the tiles as a virtual 3D model.

IDIA Lab Modeler, Trevor Danehy, explains the process, “We take at least one hundred photos of each tile, everything from straight on shots of the tile to sharp angles in an effort to expose the levels of depth in the crevices of the tile. The photogrammetry software algorithm requires that each photo has at least 50% overlap compared to the last photo taken in order to stitch together a mesh.”

“It can be a very trial and error process, so the more images taken, the better. That is why we prefer an DSLR camera that can take several images rapidly. Quantity over quality works best in photogrammetry. Once the software stitches together a crude mesh, we do a small amount of digital cleanup and export it for 3D printing.”

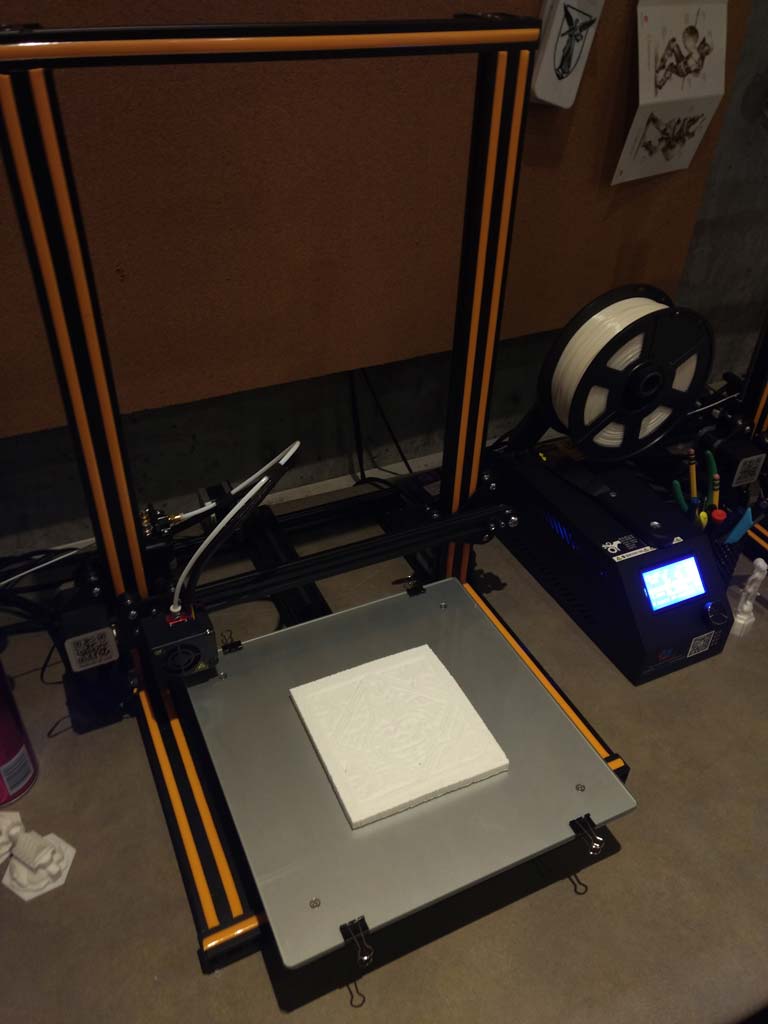

3D Printing

After the virtual mesh has been created, the next step is to recreate the tile using a physical medium. At IDIA Lab, this is accomplished using 3D printing. IDIA Lab’s Adam Kobitz, who manages 3D printing in the lab, describes the printing technique. “We printed the tiles using an Fused Deposition Modeling (FDM) printing process, in which the physical objects are built up by extruding layer after layer of melted plastic. This process allows us to produce accurate recreations of the tiles relatively quickly, permitting viewers of the exhibit to observe and interact with them in a manner they’re unable to with the original works.”

After the tiles are printed, they are ready to be displayed as a portable replica of part of Ball State’s architectural history.